AGE 1

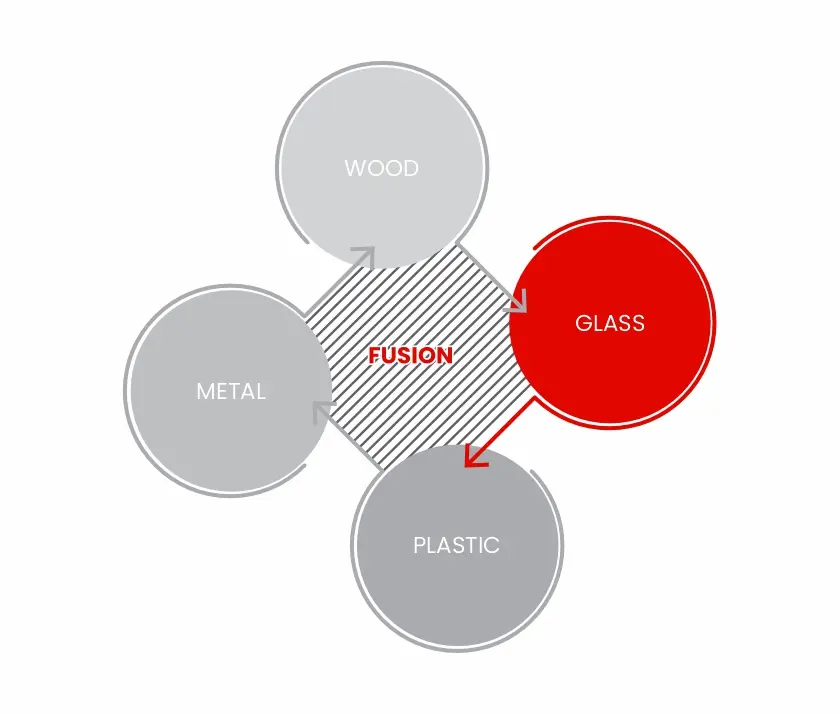

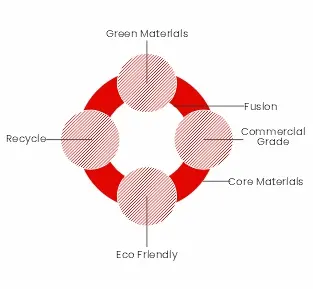

All these four core materials are placed on top of the hierarchy chart where all other products(either fused) are branched. | AGE 2

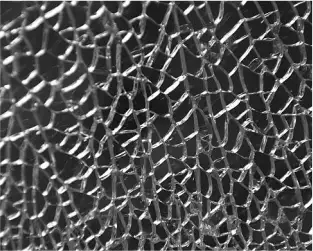

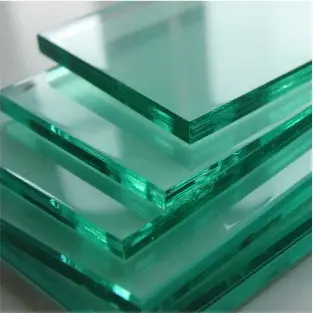

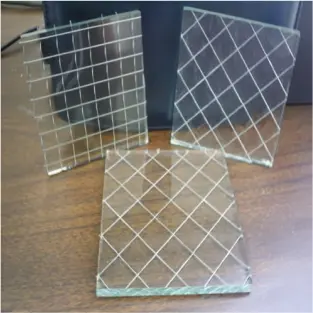

The pictograph visualizes the simple demonstration of fusion of all these core materials with other materials. The wood when engineered forms fiberboards with different densities(high, medium, low). Also, exploded wood fibers are highly compressed and the perforated hardboards are widely used to place store fixtures. The metal when fused with two or more elements forms alloys. Eg. Aluminum alloys(1xxx,2xxx,6xxx,7xxx series), copper alloys(arsenical,beryllium,billon,brass,Chinese silver etc.), Iron alloys[steel(carbon,tool,stainless), Iron-chromium, Iron-carbon], etc. Glass is commonly fused with chemical substances like (sodium, calcium)silicate, plastic, colors, wire-mesh(mainly made up of stainless steel) to make different types of glass which are widely used in home interiors, industrial, and commercial spaces, are provided by D’Art, as listed below: |